IMPACT Production Case Studies

Precast Production Management

With 5000 Employees, 5 x Precast Factories, and more than 43 years of professional experience in the Saudi Arabian market, ARA excels itself at being one of the most trusted precast concrete manufacturers in the Kingdom.

Having already utilised the 3D modelling software IMPACT Design over the past two decades, ARA decided on the next stage to implement the entire IMPACT system. Now IMPACT Production helps them track every single element from design to site.

Precast Planning in full 3D

A Paper Mill in Husum, Sweden is expanding into a large and complex construction project. The precast concrete frame is being manufactured and delivered by Attacus Stomsystem, who has used the IMPACT Precast Planning software to connect the entire workflows, from design, to production, to transport and final assembly.

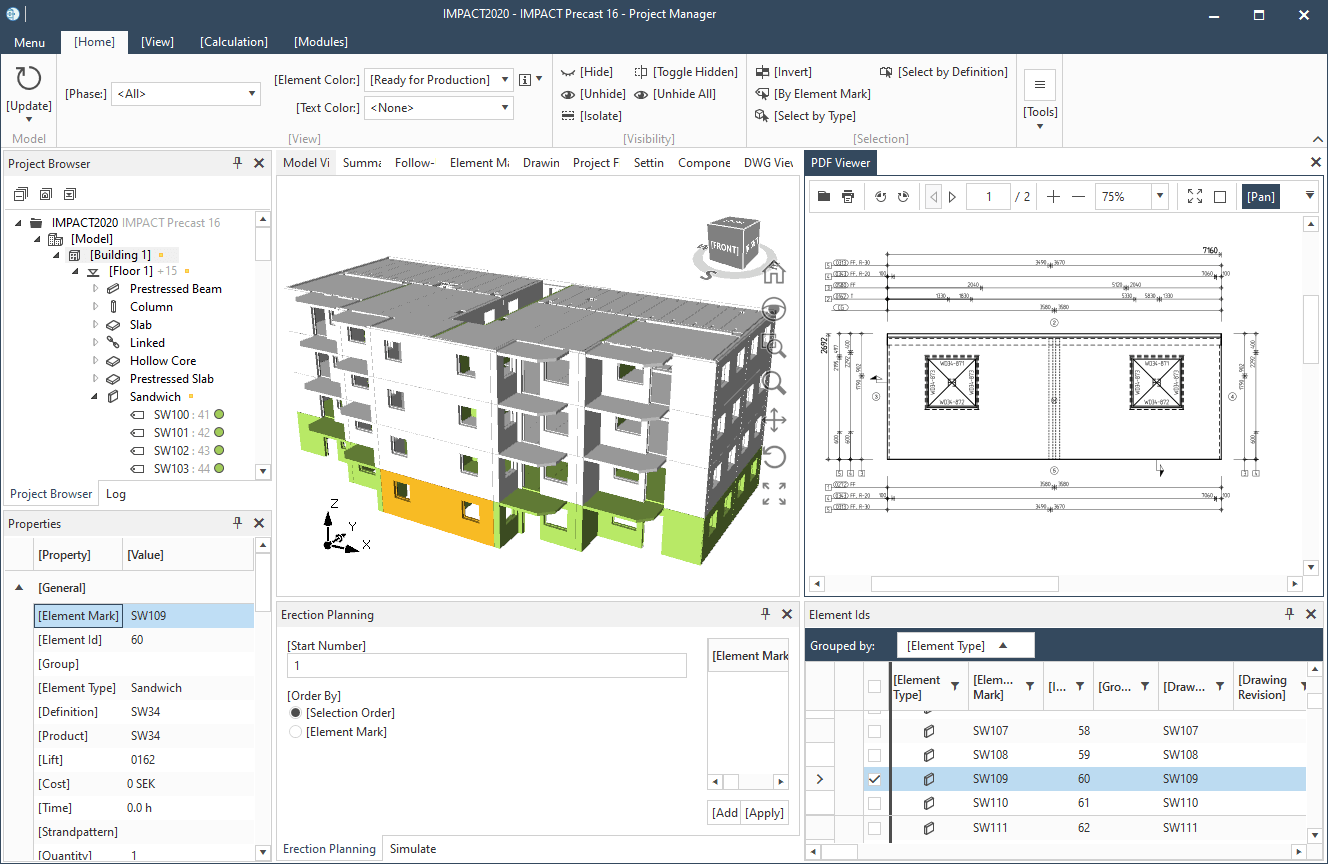

The 3D model of IMPACT Project allows intelligent visualisation of the precast elements, properties about the element and its unique ID.

The features of IMPACT Production

Characteristics:

IMPACT Project Manager offers you complete control over your precast concrete projects. This way, you can create erection sequence plans and simulations, transport deliveries, set target dates for drawings, schedule your production, and many more. Impact Project brings all your precast processes together by working with IMPACT Design and IMPACT Production.

IMPACT Project Manager features:

- Rough Planning

- Drag and drop from the 3D model

- 3D Erection Sequence Planning

- Cast Calendar

- Colour Coded

- Element Control

- Impact Go

- Data Import

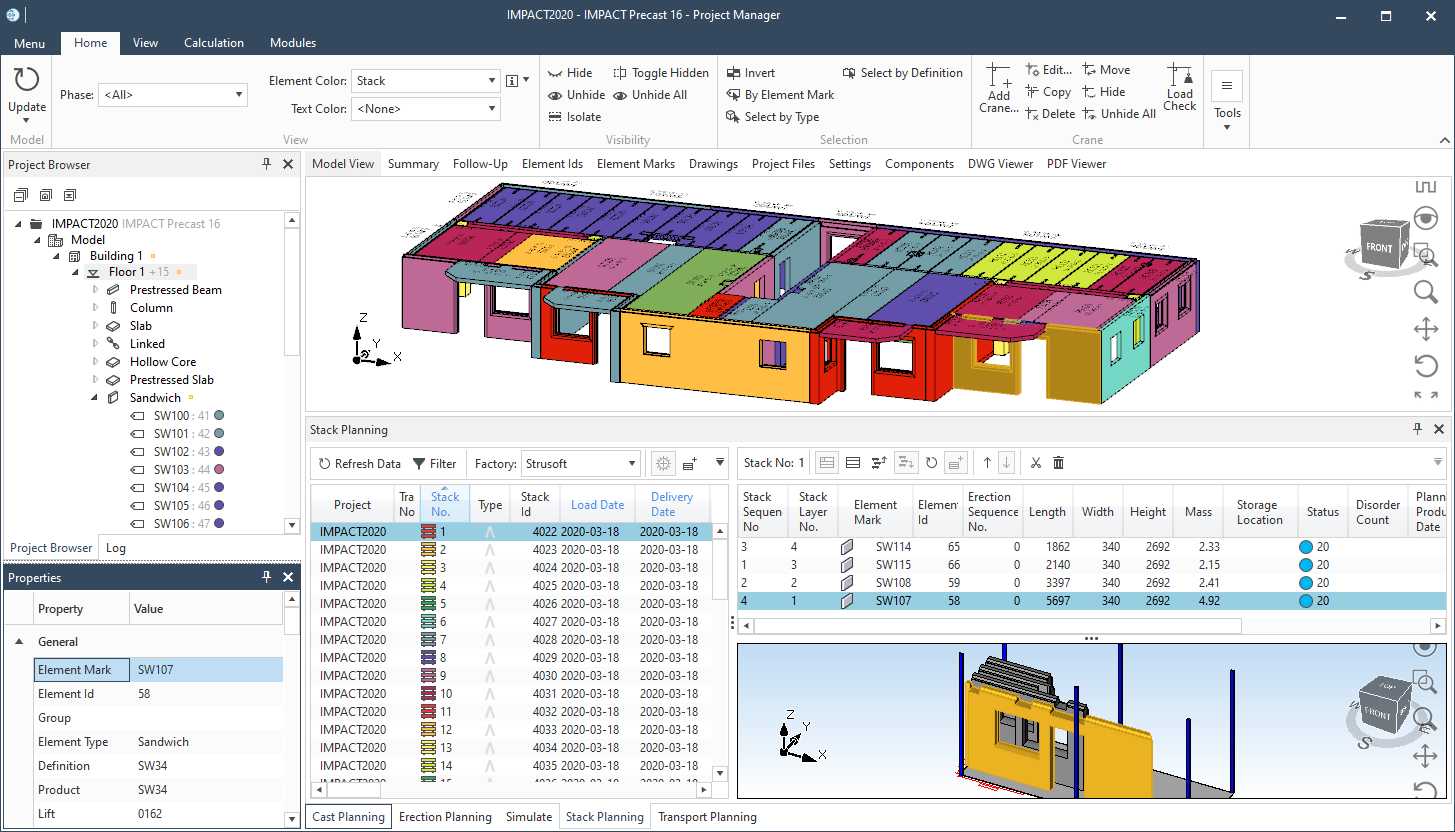

IMPACT Cast Planner is entirely customizable for your set-up in factories, production halls through to individual production beds, casting tables, and moulds. You can schedule and plan your precast production in 3D, such as solid walls, sandwich walls, hollow-core slabs, columns, beams, stairs, or any other piece imported with the linked element feature.

IMPACT Cast Planner features:

- Automatic Cast Planning

- Drag and drop from the 3D model

- 3D Cast Planning

- Cast Calendar

- Element Control

- IMPACT Go

- Data Import

IMPACT Transport Planner supports you in planning your precast concrete projects. You can use a wide diversity of vehicle models across many factory and project locations; moreover, you can mix and match various factory elements into the same vehicle. With IMPACT Transport Planner, you can load walls, sandwich walls, double (twin) walls vertically loaded on A-Frame type trailers, or filigree (form/half slabs) and hollow-core slabs horizontally loaded on flatbed trailers.

IMPACT Transport Planner features:

- Automatic Transport Planning

- Drag and drop from the 3D model

- 3D Transport Planning

- Transport Calendar

- Colour Coded

- Element Control

- IMPACT Go

- Data Import

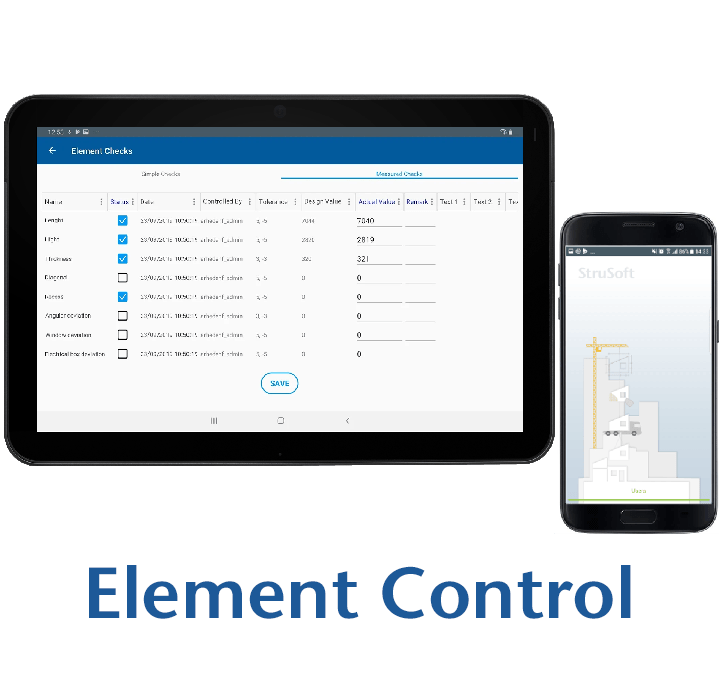

IMPACT Element Control offers you the chance to track your precast concrete elements with the click of a button. Easy to set up, it suits your existing workflows, tracks your precast elements right through production and onto projects, all in real-time and from anywhere.

IMPACT Element Control features:

- Set up any Element Control

- 3D Project Manager

- Quality Control

- QR Codes

- IMPACT Go

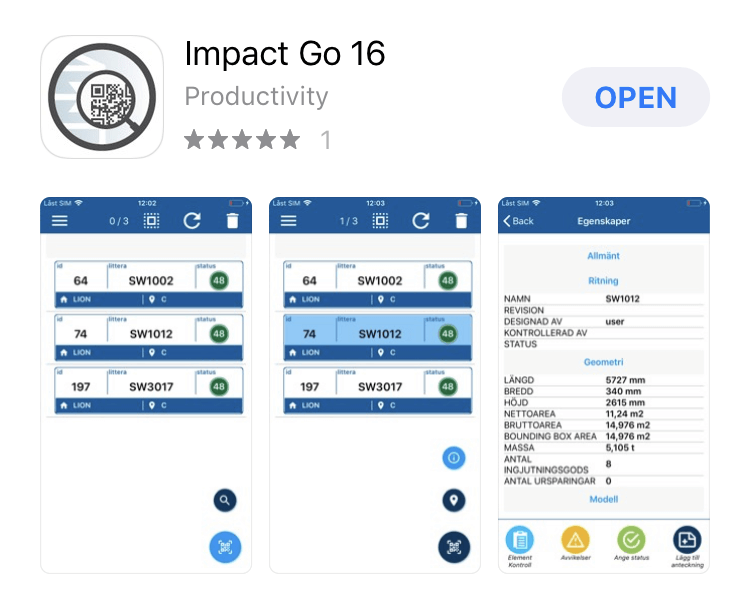

IMPACT Go enables access to the IMPACT - Structural construction software, tracking element status with detailed information and scanning QR codes to update the BIM database about element status from anywhere, at any time.

IMPACT Go features:

- Using QR-codes or search to add Elements, Casts, Stacks or Transports to the main list

- Manage storage locations

- Follow and change element status

- Set Cast Units to Produced

- Set Transport status to Call Off or Delivered

- Manage Rejections and Disorders

- Perform Element Controls

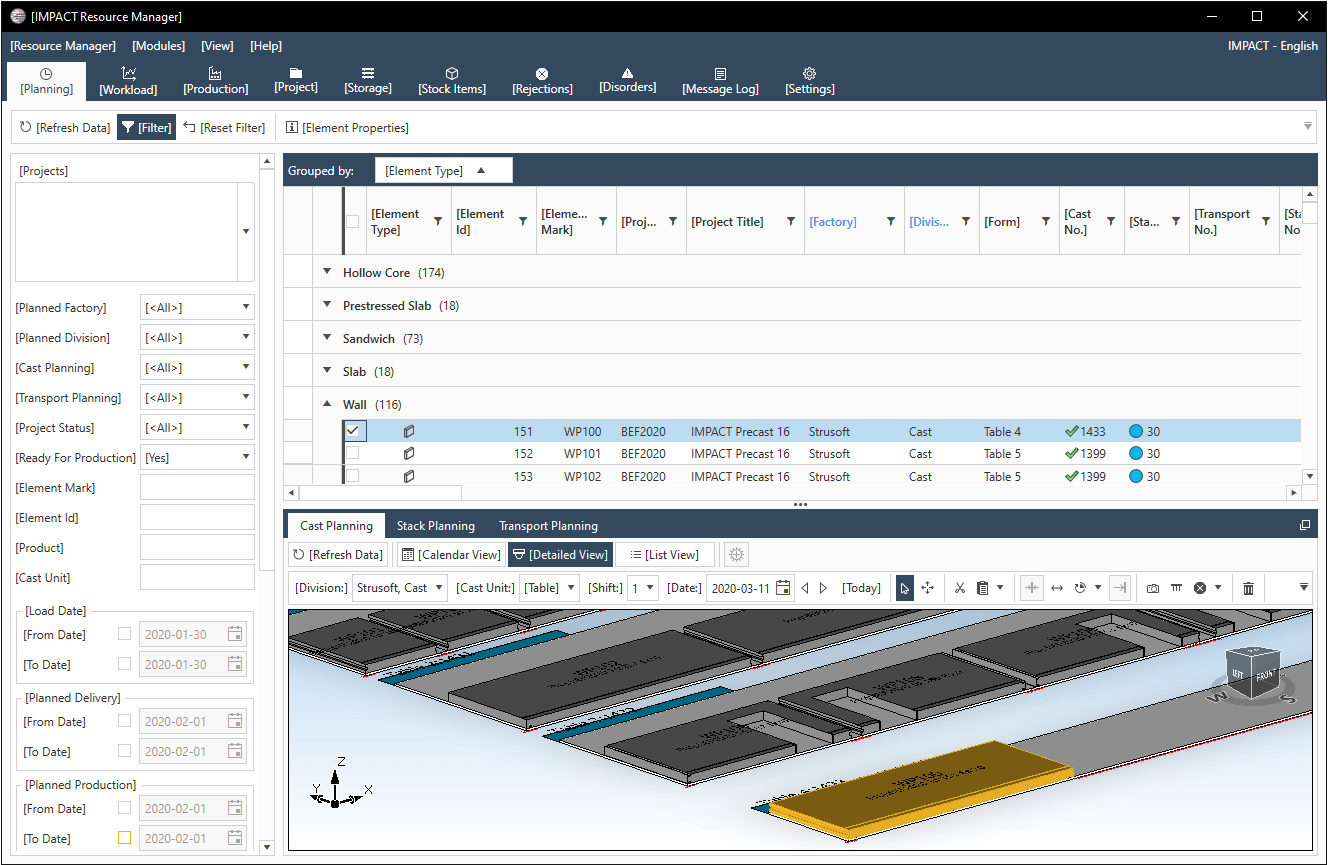

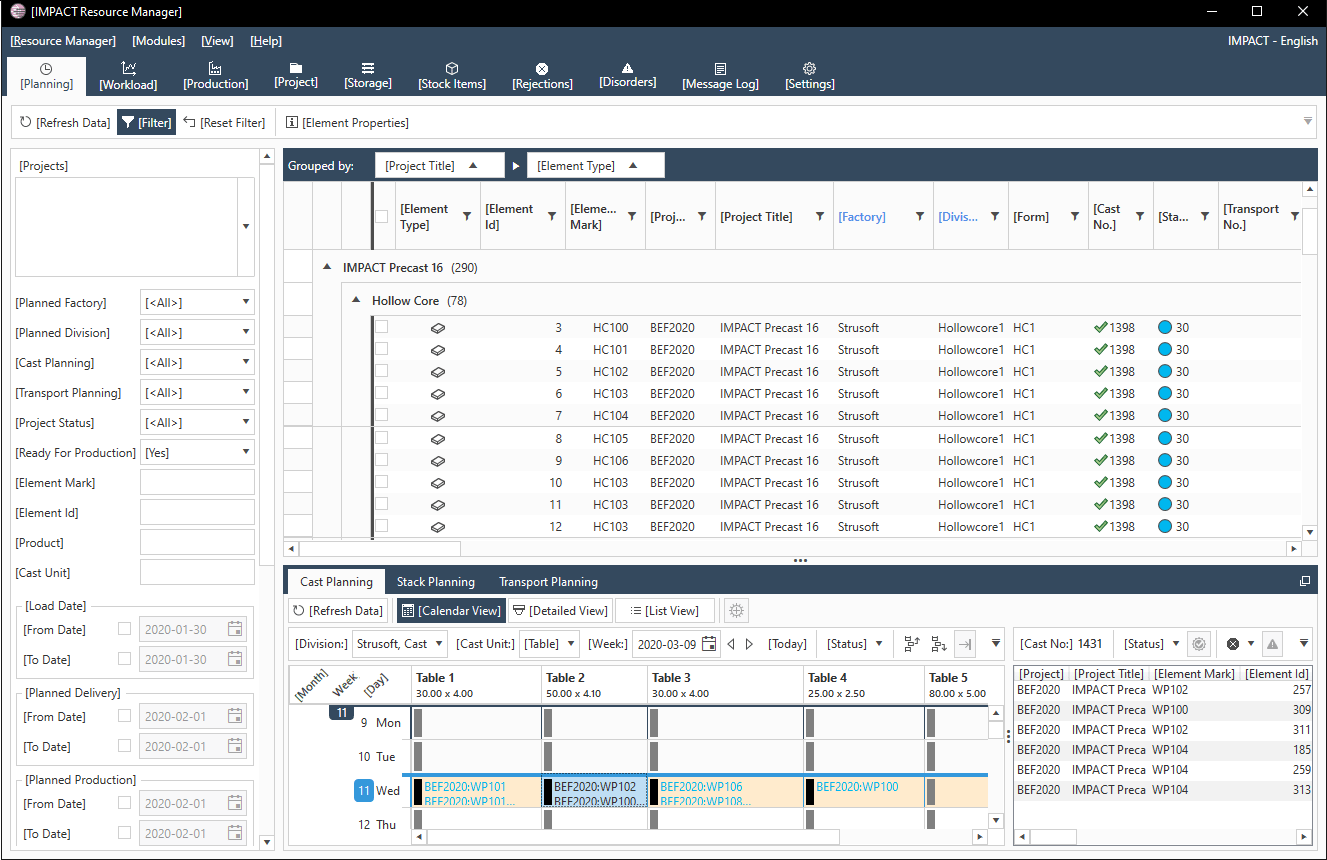

IMPACT Resource Manager is the best choice for planning and directing all your precast production and project processes, controlling element storage locations, element disorders, element rejections, element casting, any many more. You can do this across multiple projects or multiple factory locations.

IMPACT Resource Manager features:

- Rough Planning

- Cast Planning

- Transport Planning

- Calendar

- Colour Coded

- Element Control

- IMPACT Go

- Data Import

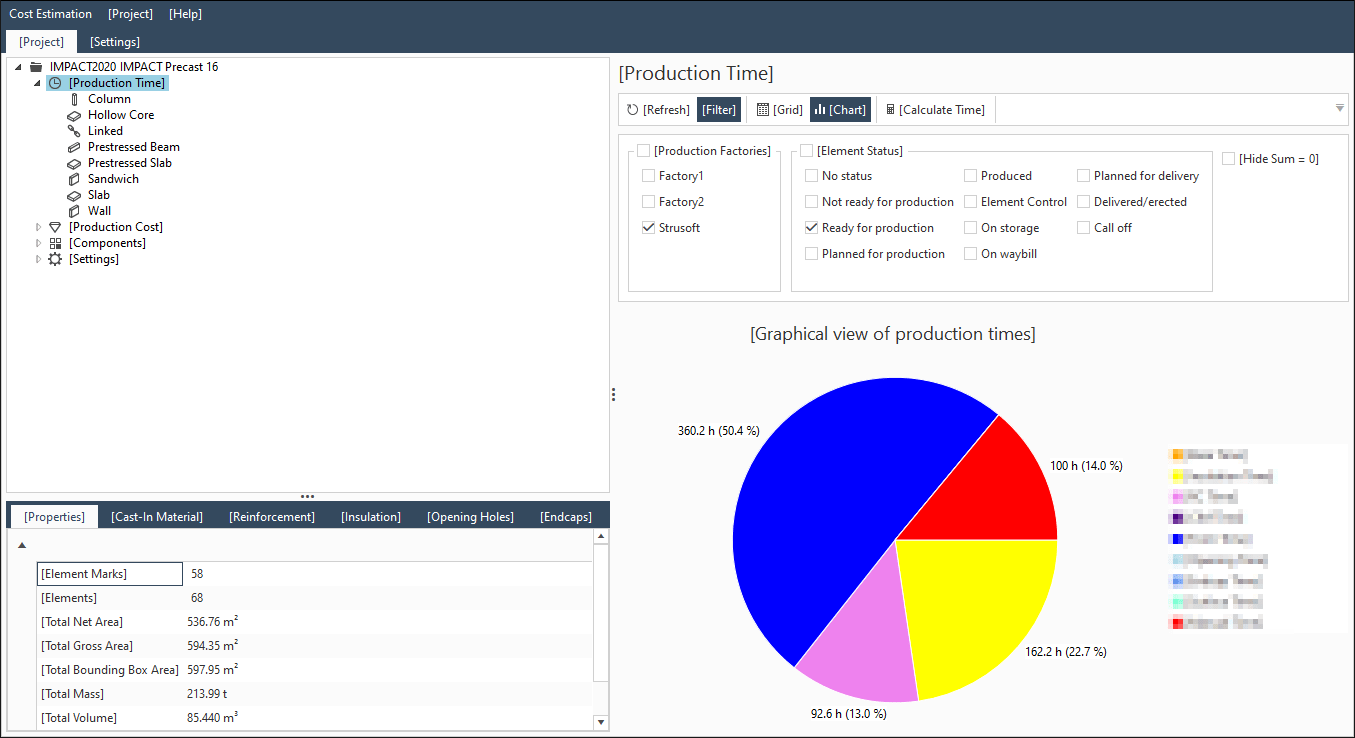

IMPACT Cost Estimation offers you the possibility to collect data on your precast projects, factories, raw materials, and labour. Quickly calculate and report accurate custom cost reports down to every hour, every single cast in the material, every reinforcement and volume of concrete used in your projects, and individual precast elements.

IMPACT Cost Estimation features:

- IMPACT Database

- Automatic Fixed Costs

- Automatic Variable Cost Calculation

- Customized Workflows

- Customized Reports

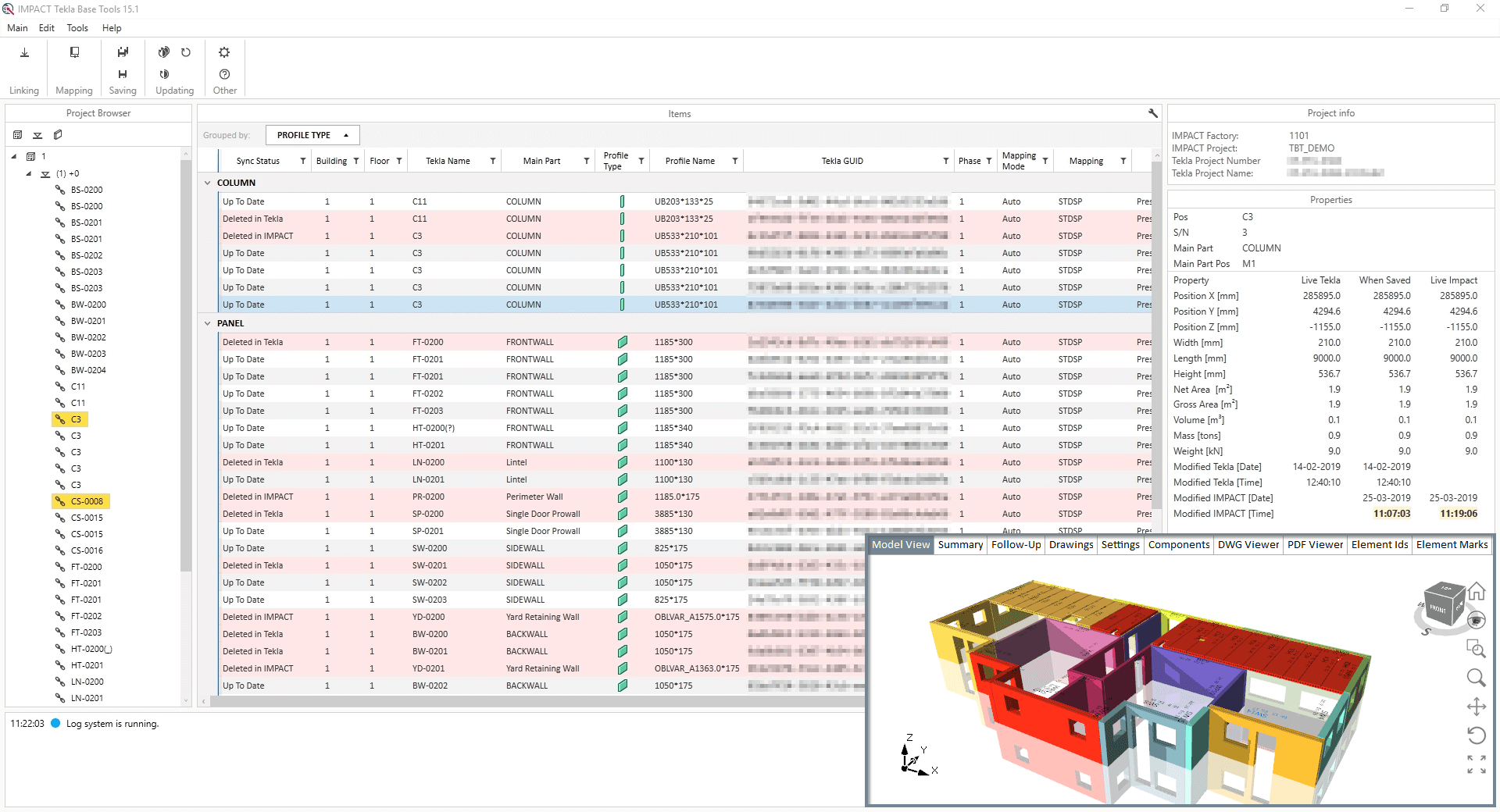

IMPACT Tekla Base Tools, together with IMPACT Production, helps you plan your Tekla projects in complete 3D. Tekla Base Tools enables you to save time while optimizing casts, transports, and managing multiple projects across multiple factories simultaneously.

IMPACT Tekla Base Tools features:

- Easily categorize your Tekla projects

- Simple user-friendly interface

- A simple, linear workflow with 3 steps

- Quickly filter to select elements and components

- Option to customize settings to meet your requirements

Compatible with

IC-Prefab

3D BIM software for production of precast walls, columns, floors and beams, including tools for project and production management, IMPACT Production is compatible with our

IC-Prefab solutions.