We are in control with Matrix Software

Mathee van de Vin

Van de Vin Doors & Windows

In charge

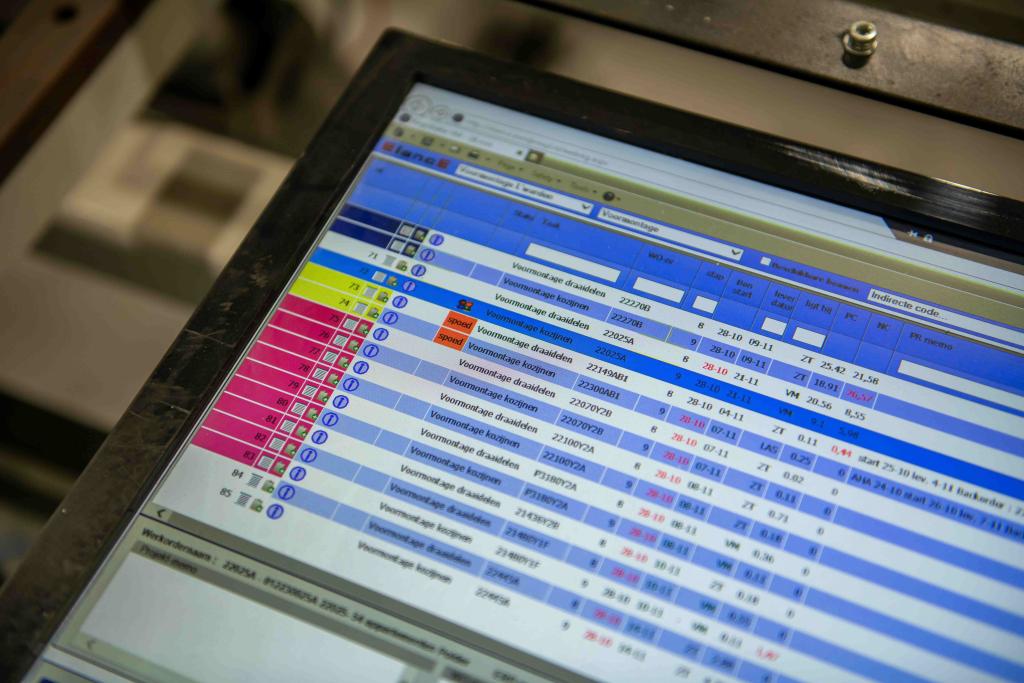

It is a special combination that Van de Vin Windows and Frames has made with regard to automation: on the one hand the company only works with software that has been proven in practice, on the other it gives direction to the development and the company tests the latest versions of software. "This way we ensure that we are in charge, that we use automation optimally," says director Mathee van de Vin. Van de Vin has been chairman of the Dutch Association of Windows and Frames and also knows the branch well from that position. For example, he knows that the switch to new software for producers of windows and frames is no sinecure. "Think very carefully before you choose", is his advice. "Because once chosen it is difficult to still change the beacons."

|

|

|

More benefits

Van de Vin himself chose Matrix Software in 1988. He still knows how it went the day of yesterday. "The company had acquired the first PC two years earlier. In 1988 we were one of the first users of MatrixKozijn, the program with which we made calculations and streamlined the work preparation. It was then very much getting used to. All of a sudden, data had to be entered in detail. The time that you made an offer based on intuition was suddenly over. "At that time, Van de Vin was mainly concerned about getting accurate information about more and less work. Soon it turned out that there were many more benefits. "Thanks to MatrixKozijn and Matrix's time registration system, the chance of errors and failure costs has been reduced significantly. We also save a lot of time, although we find it so common that we hardly consider it an advantage. "Time has not stood still. Van de Vin has recently switched to a completely new machine park. "Such a switch can be a reason to look at what else is on the market, but we have never seriously considered this consideration. We are very satisfied with what we have and that is not only due to the functionality of the software. The company that supports it is also important. Matrix Software is a stable, solid company with employees that we have pleasant contact with. "

|

|

|

Test company

That contact has been intensified recently, because Van de Vin Windows and Frames is a test company for Matrix Software: new versions of software are judged by a limited number of users to see what is good or bad. "With the switch to the Windows version we were richly late at the time. That was a conscious choice, we wanted to know for sure that all primary errors were out. It therefore seems strange that we are now trying to work with the latest of the latest. Yet that is logical. We want to be in charge, to be at the cradle of new developments and to benefit from that in the future. This can be done by testing new programs. "Despite his satisfaction, Van de Vin still has specific wishes. "We can not process the connection between window frames and walls completely automatically, because there are far too many variations. They can not possibly be cost-effectively placed in a single database. We will continue doing so for the time being. "According to the director, reducing the number of variations is not an option. "No thinking about it, the enormous amount of possibilities is the big advantage of wooden window frames. We must cherish that." (In the meantime, Matrix Software has establised a solution for this)

About Van de Vin Windows and Frames

Van

de Vin Ramen and Kozijnen in Heeze works from the realization that windows and

window frames largely determine the atmosphere of a home. The company has been

producing windows and frames for more than fifty years and is regarded as a

'total solution' in that area. Van de Vin supplies products thanks tot strict

process and quality control. It is produced according to a proven method, of

which the quality assurance system has been developed together with TNO. This

system offers Van de Vin, together with an advanced machine park and advanced

automation, the possibility of further innovation.

Van

de Vin Ramen and Kozijnen in Heeze works from the realization that windows and

window frames largely determine the atmosphere of a home. The company has been

producing windows and frames for more than fifty years and is regarded as a

'total solution' in that area. Van de Vin supplies products thanks tot strict

process and quality control. It is produced according to a proven method, of

which the quality assurance system has been developed together with TNO. This

system offers Van de Vin, together with an advanced machine park and advanced

automation, the possibility of further innovation.

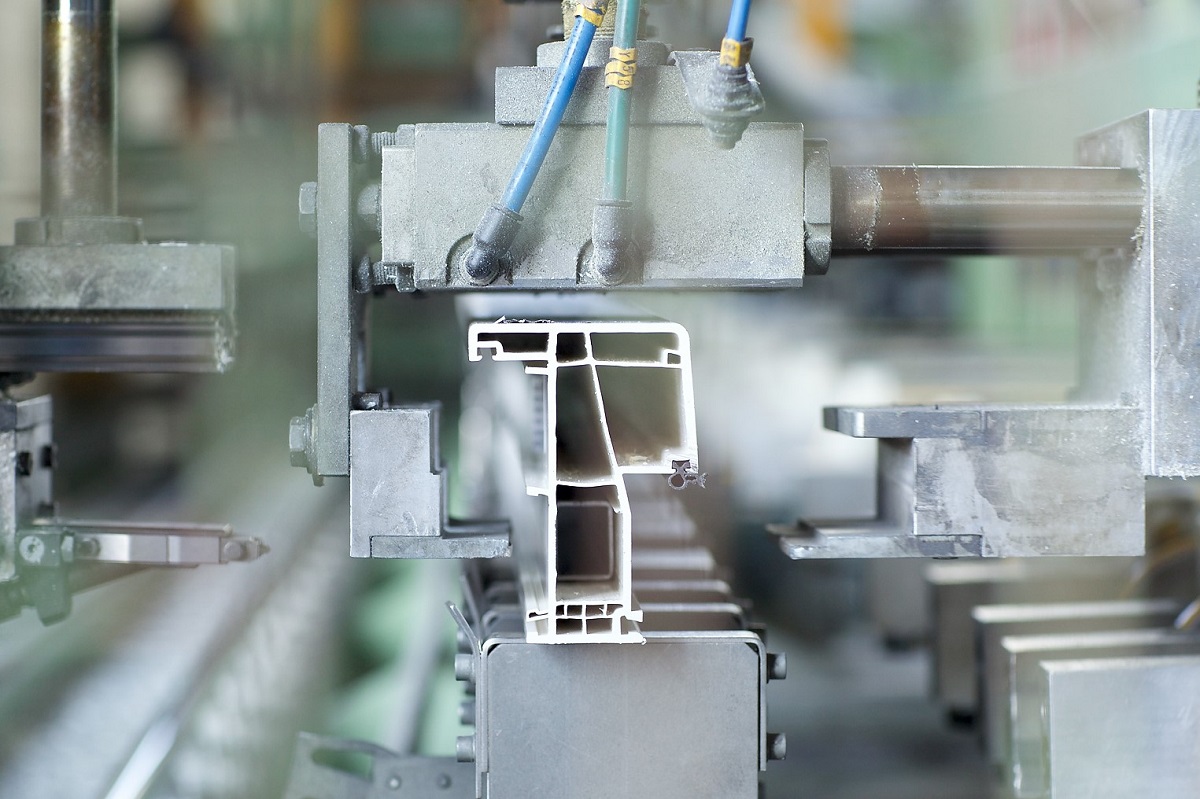

Kumij

is based in Groningen and is part of the Rollecate Group, a leading manufacturer

of plastic frames, which supplies and installs its frames throughout the

Netherlands. The high-quality plastic frames are used in renovation and new

construction projects for housing corporations, contractors, architects and

owners' associations. Kumij's flexible project organization has more than 120

employees and has more than 55 years of experience in providing customized

solutions in the area of window frames. Attention is paid to profiling,

detailing and construction, but also to building coordination, residents'

information and delivery.

Kumij

is based in Groningen and is part of the Rollecate Group, a leading manufacturer

of plastic frames, which supplies and installs its frames throughout the

Netherlands. The high-quality plastic frames are used in renovation and new

construction projects for housing corporations, contractors, architects and

owners' associations. Kumij's flexible project organization has more than 120

employees and has more than 55 years of experience in providing customized

solutions in the area of window frames. Attention is paid to profiling,

detailing and construction, but also to building coordination, residents'

information and delivery.

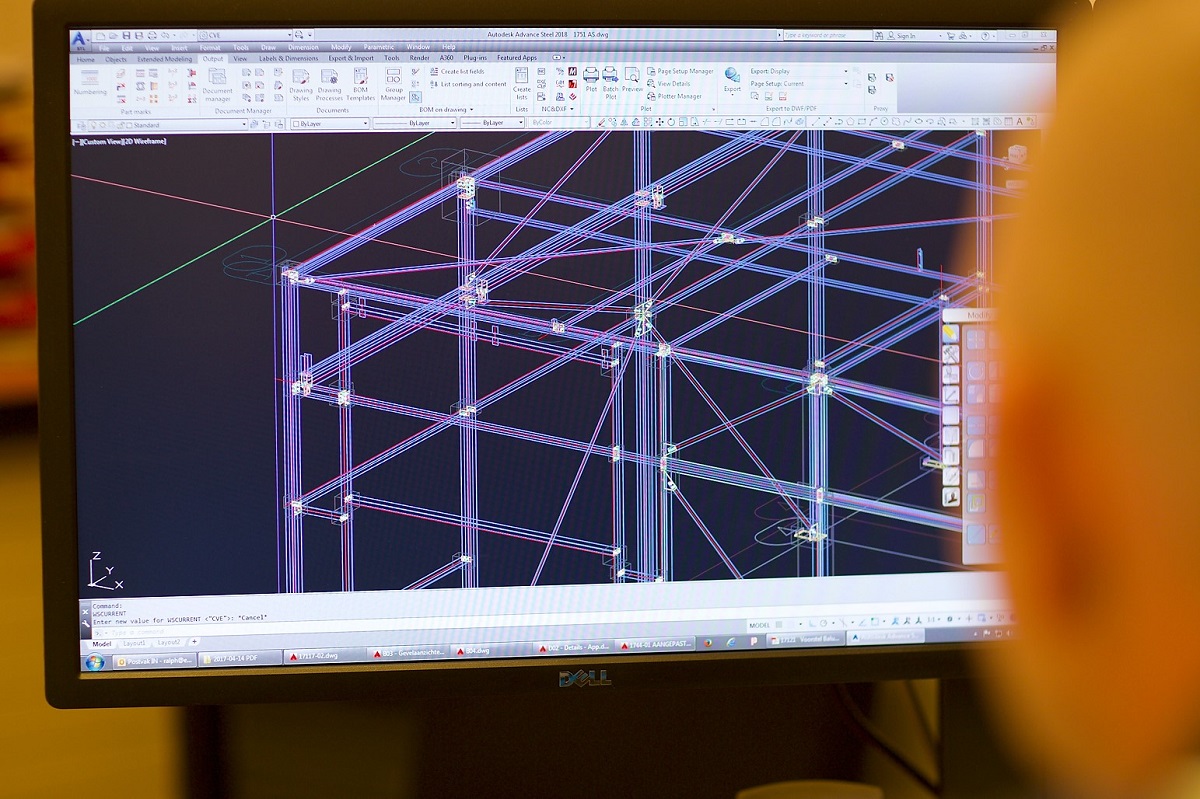

Goudriaan

BV was founded in 1969 by Gert Goudriaan and is now led by his son Johan. In

half a century the company in Oudewater has become a household name in the steel

industry, characterized by craftsmanship, creativity, innovative capacity and

thinking along with the customer. Goudriaan BV also has its own design and

engineering department. Production takes place in large halls with modern

machines. The supply range consists of a wide range of products in steel,

stainless steel and aluminum. This varies from steel from stock and large steel

constructions to steel stairs, fences, balustrades and sheet metal. Nearly all

operations are possible, such as drilling holes, welding, miter sawing,

galvanizing, powder coating and spraying. With 35 highly professional employees,

all knowledge and experience is available to deliver a technically high-quality

product. Goudriaan BV is a recognized training company, affiliated with the

trade union Metaalunie and of course VCA and CE EN1090-1 certified.

Goudriaan

BV was founded in 1969 by Gert Goudriaan and is now led by his son Johan. In

half a century the company in Oudewater has become a household name in the steel

industry, characterized by craftsmanship, creativity, innovative capacity and

thinking along with the customer. Goudriaan BV also has its own design and

engineering department. Production takes place in large halls with modern

machines. The supply range consists of a wide range of products in steel,

stainless steel and aluminum. This varies from steel from stock and large steel

constructions to steel stairs, fences, balustrades and sheet metal. Nearly all

operations are possible, such as drilling holes, welding, miter sawing,

galvanizing, powder coating and spraying. With 35 highly professional employees,

all knowledge and experience is available to deliver a technically high-quality

product. Goudriaan BV is a recognized training company, affiliated with the

trade union Metaalunie and of course VCA and CE EN1090-1 certified.

Mechanical joinery Van der Linden is a no-nonsense family business, that is already

since 1974 commitment to perfect and beautiful carpentry. Quality always stands

first and foremost, the bar is high, whether it concerns complex customization or series work. From

der Linden works with passion for both contractors and private individuals. Because all

more than 20 employees are all-round professionals, the company has few limitations

in its product range. The assignments therefore vary from window frames and doors

to stairs, dormer windows, fronts, (folding) walls, fencing and more. At Van der

Linden go hand in hand with entrepreneurship and craftsmanship. On the one hand it ensures

high-quality machinery for unrivaled accuracy. On the other hand still manages

the entire team of professionals always the old-fashioned craft. The result:

carpentry where Van der Linden is proud of.

Mechanical joinery Van der Linden is a no-nonsense family business, that is already

since 1974 commitment to perfect and beautiful carpentry. Quality always stands

first and foremost, the bar is high, whether it concerns complex customization or series work. From

der Linden works with passion for both contractors and private individuals. Because all

more than 20 employees are all-round professionals, the company has few limitations

in its product range. The assignments therefore vary from window frames and doors

to stairs, dormer windows, fronts, (folding) walls, fencing and more. At Van der

Linden go hand in hand with entrepreneurship and craftsmanship. On the one hand it ensures

high-quality machinery for unrivaled accuracy. On the other hand still manages

the entire team of professionals always the old-fashioned craft. The result:

carpentry where Van der Linden is proud of.

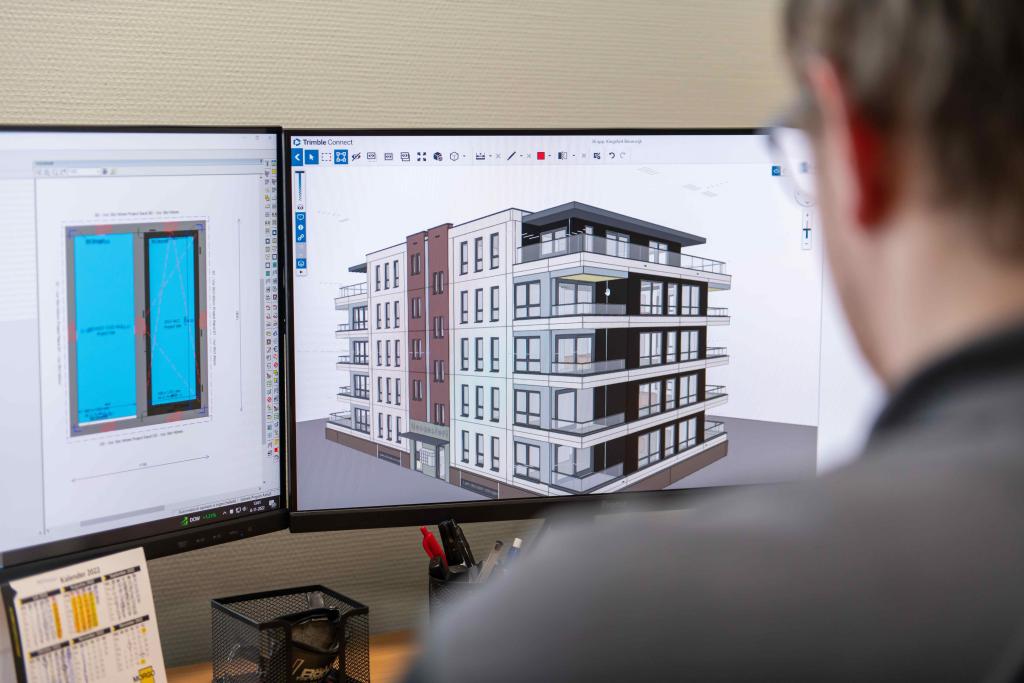

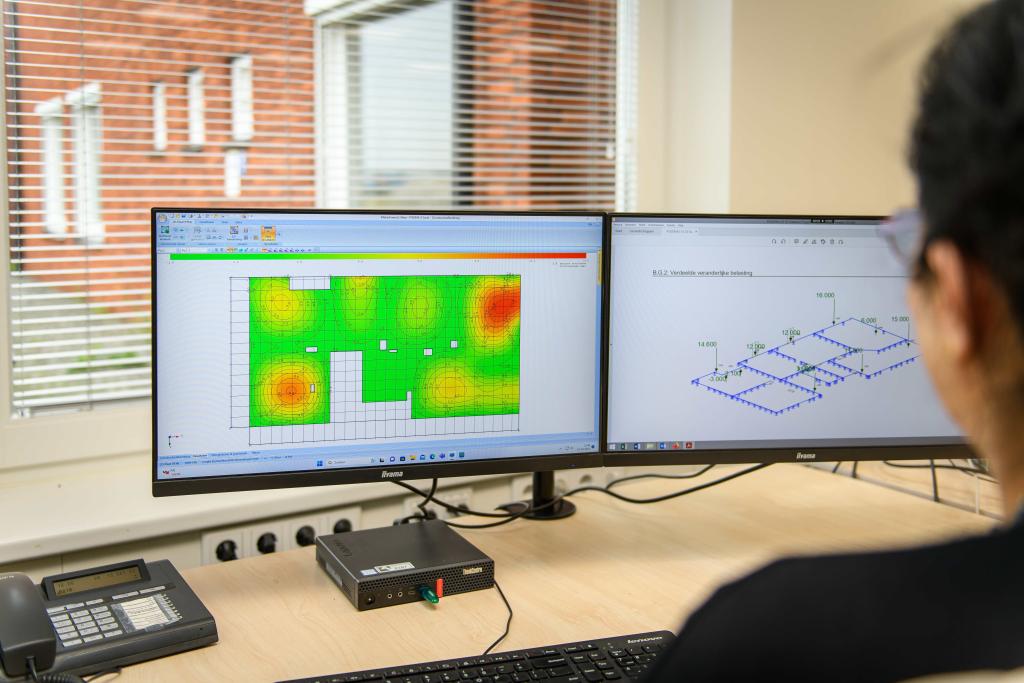

Van

Boxsel Engineering has been a professional and involved partner in construction

for almost 50 years. The consultants, project managers, constructors, drafters

and 3D modellers work on a wide range of building constructions - with a special

focus on precast concrete constructions. The work covers all phases from design,

building permit, specifications to detailed engineering and realization. In the

field of 3D modeling in combination with BIM, Van Boxsel has extensive expertise

from the design phase until well into the execution phase. The company likes to

use personal knowledge for an integral approach to projects in their

environment. To then transfer this experience directly to the client via

'augmented reality'. This way, it can gain better insight into the project and

be informed in an optimal way. Van Boxsel also has a branch in India, which

serves large parts of the Anglo-Saxon market, from America to Australia.

Van

Boxsel Engineering has been a professional and involved partner in construction

for almost 50 years. The consultants, project managers, constructors, drafters

and 3D modellers work on a wide range of building constructions - with a special

focus on precast concrete constructions. The work covers all phases from design,

building permit, specifications to detailed engineering and realization. In the

field of 3D modeling in combination with BIM, Van Boxsel has extensive expertise

from the design phase until well into the execution phase. The company likes to

use personal knowledge for an integral approach to projects in their

environment. To then transfer this experience directly to the client via

'augmented reality'. This way, it can gain better insight into the project and

be informed in an optimal way. Van Boxsel also has a branch in India, which

serves large parts of the Anglo-Saxon market, from America to Australia.

Bureau

Broersma (The Hague) has been advising on the properties and performance of

structures since 1956. About 18.000 projects have now been completed, previously

mainly in concrete and steel, nowadays in all possible construction materials.

The agency makes drawings and calculations of almost all common building

constructions. The field of work extends from utility and residential

construction to oil rigs and industrial and logistic complexes. From a permanent

'drive' to push boundaries, Bureau Broersma regularly offers internships. This

allows experienced specialists to transfer their knowledge to a new generation,

while the agency reaps the benefits of all the insights and innovative solutions

that technical students introduce from their training. The whole of this

knowledge is therefore greater than the sum of the parts, with which Bureau

Broersma offers an important added value.

Bureau

Broersma (The Hague) has been advising on the properties and performance of

structures since 1956. About 18.000 projects have now been completed, previously

mainly in concrete and steel, nowadays in all possible construction materials.

The agency makes drawings and calculations of almost all common building

constructions. The field of work extends from utility and residential

construction to oil rigs and industrial and logistic complexes. From a permanent

'drive' to push boundaries, Bureau Broersma regularly offers internships. This

allows experienced specialists to transfer their knowledge to a new generation,

while the agency reaps the benefits of all the insights and innovative solutions

that technical students introduce from their training. The whole of this

knowledge is therefore greater than the sum of the parts, with which Bureau

Broersma offers an important added value.

Timmerfabriek WHB Sneek is a real family business. Founded in 2008 by the two

cousins Wiersma, the company is known as a reliable partner for small

construction companies and self-employed entrepreneurs. In our own factory a

small but driven team produces high-quality window frames, windows and doors to

size and delivers them with or without glass. In addition,

environmentally-friendly wood species are used extensively. WHB Sneek has

everything it takes to deliver not only large batches, but also small series and

even individuals in ever-changing sizes. The specialists at WHB Sneek know and

exploit the infinite application possibilities of wood as a building material

for residential and non-residential building projects. Thanks to this extensive

expertise, clients know that they can always expect the highest quality. The

products of WHB Sneek are successfully applied in the most diverse new

construction and renovation projects.

Timmerfabriek WHB Sneek is a real family business. Founded in 2008 by the two

cousins Wiersma, the company is known as a reliable partner for small

construction companies and self-employed entrepreneurs. In our own factory a

small but driven team produces high-quality window frames, windows and doors to

size and delivers them with or without glass. In addition,

environmentally-friendly wood species are used extensively. WHB Sneek has

everything it takes to deliver not only large batches, but also small series and

even individuals in ever-changing sizes. The specialists at WHB Sneek know and

exploit the infinite application possibilities of wood as a building material

for residential and non-residential building projects. Thanks to this extensive

expertise, clients know that they can always expect the highest quality. The

products of WHB Sneek are successfully applied in the most diverse new

construction and renovation projects.

Breetec

International NV, located in the Flemish Axis, is a supplier of safety valves,

constructions and sheet metal in aluminum, stainless steel and steel, aluminum

flanges and fittings. The company has a large team for assembly and maintenance

work. For clients, Breetec provides both engineering, production, logistics,

assembly and maintenance. Quality, safety and training are the most important

pillars in business management.

Breetec

International NV, located in the Flemish Axis, is a supplier of safety valves,

constructions and sheet metal in aluminum, stainless steel and steel, aluminum

flanges and fittings. The company has a large team for assembly and maintenance

work. For clients, Breetec provides both engineering, production, logistics,

assembly and maintenance. Quality, safety and training are the most important

pillars in business management.

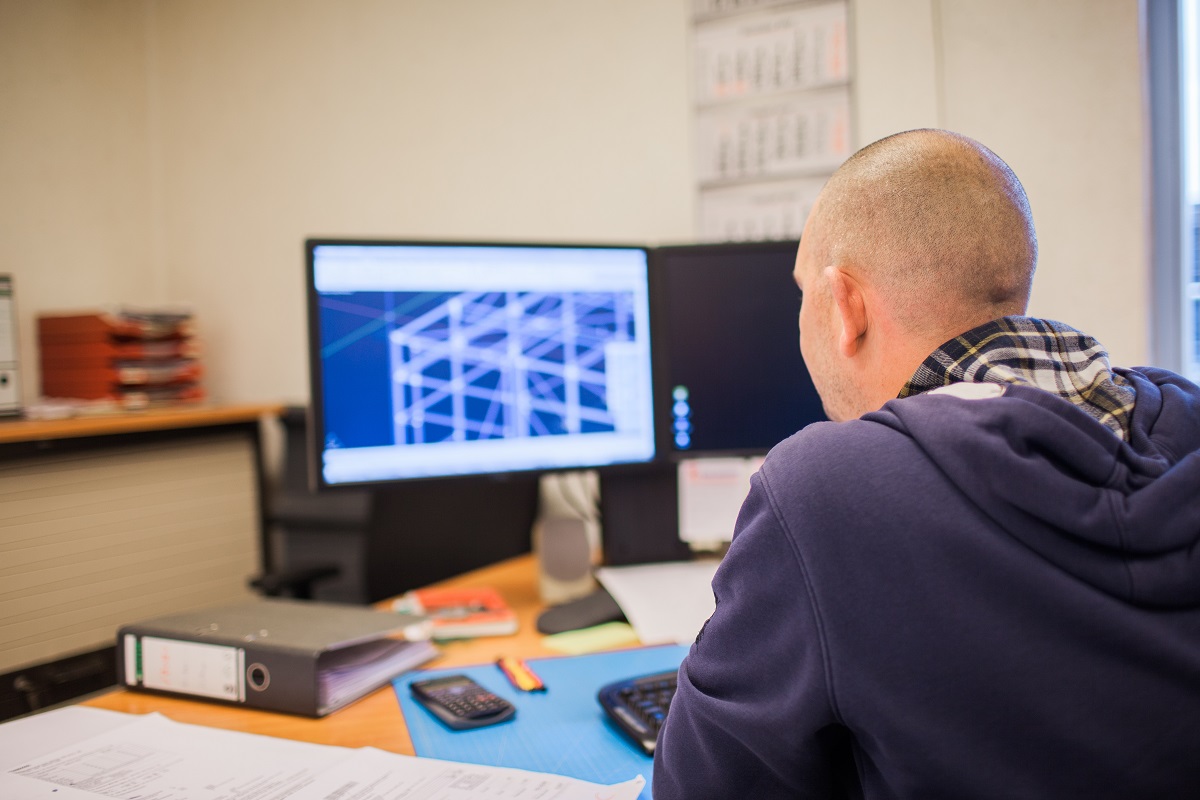

Ingenieursbureau

Van Roekel & Van Roekel, founded in 1973, is an independent consultancy for

civil engineering. The firm specializes in concrete, steel and timber

constructions, foundations and geotechnical constructions. Clients include

architectural firms, contracting companies, steel construction companies,

project developers, housing corporations, chain stores, private individuals and

industry. Architectural structures for buildings and constructions form the most

important activity (85%), in addition to hydraulic engineering works (15%). Van

Roekel & Van Roekel has always worked extensively for clients in the steel

construction industry, creating a unique expertise. The firm handles the entire

process, including design calculations for the calculation departments of steel

companies, main calculations of the complete construction for the permits and

the specifications, and detailed calculations of connections for the execution.

The agency also regularly makes second opinions or shadow designs for steel

constructions in order to achieve a more economical or more feasible steel

construction.

Ingenieursbureau

Van Roekel & Van Roekel, founded in 1973, is an independent consultancy for

civil engineering. The firm specializes in concrete, steel and timber

constructions, foundations and geotechnical constructions. Clients include

architectural firms, contracting companies, steel construction companies,

project developers, housing corporations, chain stores, private individuals and

industry. Architectural structures for buildings and constructions form the most

important activity (85%), in addition to hydraulic engineering works (15%). Van

Roekel & Van Roekel has always worked extensively for clients in the steel

construction industry, creating a unique expertise. The firm handles the entire

process, including design calculations for the calculation departments of steel

companies, main calculations of the complete construction for the permits and

the specifications, and detailed calculations of connections for the execution.

The agency also regularly makes second opinions or shadow designs for steel

constructions in order to achieve a more economical or more feasible steel

construction.

Timmerfabriek Timboco was founded in 1978 by Fokke van Houten. With his son, Rick van Houten, the second generation is now at the helm of the family business, which produces wooden frames, windows and doors and timber-frame construction elements, particularly for residential construction, from new construction to renovation from ground-level homes to apartment buildings. A team of 45 professionals is committed to making the most beautiful products daily. But also, to guarantee consistent quality.

Timmerfabriek Timboco was founded in 1978 by Fokke van Houten. With his son, Rick van Houten, the second generation is now at the helm of the family business, which produces wooden frames, windows and doors and timber-frame construction elements, particularly for residential construction, from new construction to renovation from ground-level homes to apartment buildings. A team of 45 professionals is committed to making the most beautiful products daily. But also, to guarantee consistent quality.

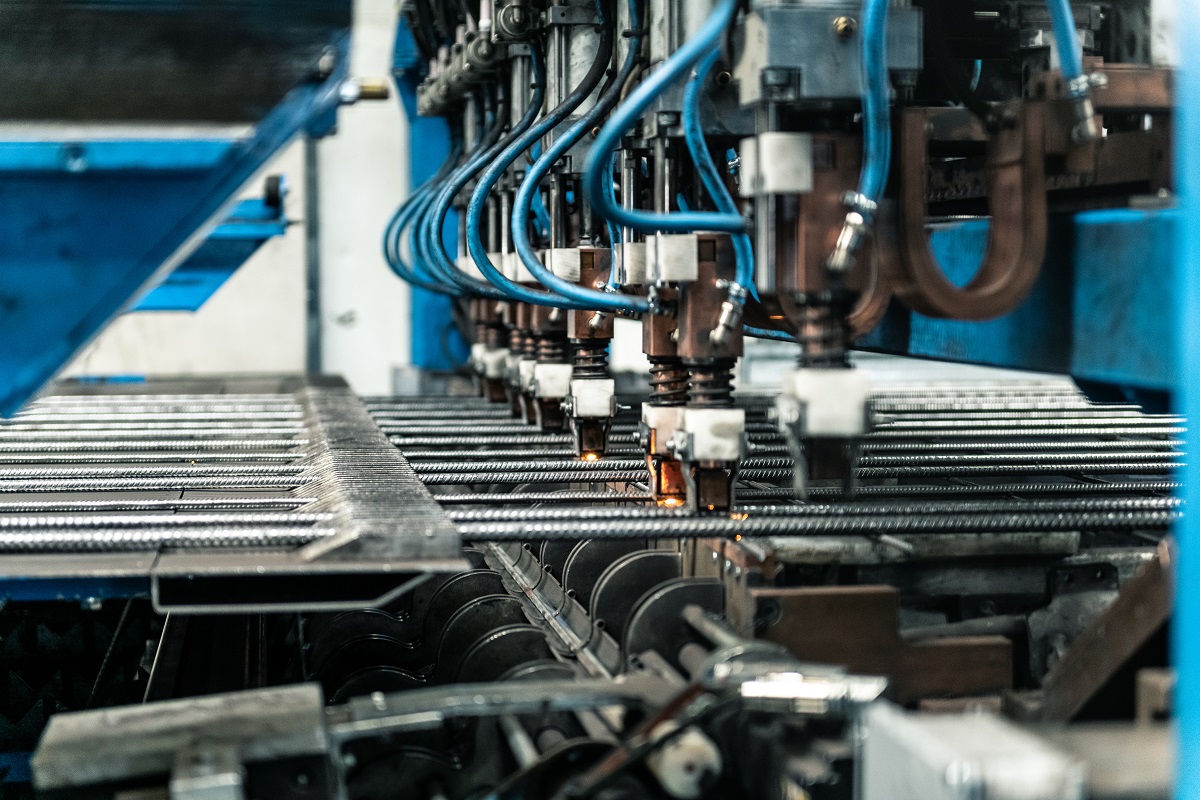

Geelen Concrete has a long history as a family business. Founded in 1923, the

factory initially focused on the manual manufacture of concrete products.

The emphasis was immediately on quality, reliability and innovation.

In two very modern factories in Wanssum and Posterholt become the most

various system floors and concrete elements manufactured. As one of the

Geelen Beton has the people and the resources to be major players in the market

translate all questions from clients into prefab concrete elements with a

great aesthetic value. The engineering takes place completely in-company,

complex construction issues are not avoided. Also

the company contributes to the development of new production techniques, with

an emphasis on sustainability. This is partly due to the use of modern

technical and digital tools, and through close cooperation with external

experts, scientists and suppliers.

Geelen Concrete has a long history as a family business. Founded in 1923, the

factory initially focused on the manual manufacture of concrete products.

The emphasis was immediately on quality, reliability and innovation.

In two very modern factories in Wanssum and Posterholt become the most

various system floors and concrete elements manufactured. As one of the

Geelen Beton has the people and the resources to be major players in the market

translate all questions from clients into prefab concrete elements with a

great aesthetic value. The engineering takes place completely in-company,

complex construction issues are not avoided. Also

the company contributes to the development of new production techniques, with

an emphasis on sustainability. This is partly due to the use of modern

technical and digital tools, and through close cooperation with external

experts, scientists and suppliers.

What

started as a smithy a century ago, has developed into a modern construction

company with more than 20 employees, especially in the last few decades. Joosten

Staalbouw specializes in the manufacture and assembly of steel constructions for

non-residential construction and industry. The company also produces the

associated parts such as stairs, platforms, handrails and fences. Very varied

steelwork is tailor-made for residential construction. At Joosten Staalbouw,

craftsmanship and perfect end result are central. The company is VCA *

-certified and all production and assembly workers are certified according to

the welding standard NEN-EN 287-1. For customers, Joosten Staalbouw has a number

of certainties such as: one point of contact from tender to completion, a

customer-oriented and flexible mentality, short delivery times and punctual

schedules. Joosten Staalbouw is also socially involved and sponsor of Médecins

Sans Frontières, Wouters Sportfonds and Weeshuys Aceh.

What

started as a smithy a century ago, has developed into a modern construction

company with more than 20 employees, especially in the last few decades. Joosten

Staalbouw specializes in the manufacture and assembly of steel constructions for

non-residential construction and industry. The company also produces the

associated parts such as stairs, platforms, handrails and fences. Very varied

steelwork is tailor-made for residential construction. At Joosten Staalbouw,

craftsmanship and perfect end result are central. The company is VCA *

-certified and all production and assembly workers are certified according to

the welding standard NEN-EN 287-1. For customers, Joosten Staalbouw has a number

of certainties such as: one point of contact from tender to completion, a

customer-oriented and flexible mentality, short delivery times and punctual

schedules. Joosten Staalbouw is also socially involved and sponsor of Médecins

Sans Frontières, Wouters Sportfonds and Weeshuys Aceh.

Van Eekert Constructions in Bladel (1978) has been specialized for 40 years in the

production and assembly of customized steel constructions, steel staircases and

balustrades. The steel parts are produced according to the NEN1090 standard so

that all end products have a CE mark. The company also supplies and assembles

roof and wall cladding at work, especially for asbestos removal. The assignments

range from large-scale (such as the new building of sports halls and schools) to

small-scale ones (such as a renovation or new construction of a house). With 15

employees involved in internal and external service, Van Eekert gives 100%

personal attention to every client, from contractor to private individual.

Because no assignment is the same, customization is the rule rather than the

exception.

Van Eekert Constructions in Bladel (1978) has been specialized for 40 years in the

production and assembly of customized steel constructions, steel staircases and

balustrades. The steel parts are produced according to the NEN1090 standard so

that all end products have a CE mark. The company also supplies and assembles

roof and wall cladding at work, especially for asbestos removal. The assignments

range from large-scale (such as the new building of sports halls and schools) to

small-scale ones (such as a renovation or new construction of a house). With 15

employees involved in internal and external service, Van Eekert gives 100%

personal attention to every client, from contractor to private individual.

Because no assignment is the same, customization is the rule rather than the

exception.

KUFA

Window systems is the leading manufacturer of plastic frames. This fast-growing

company, founded in 2009, provides an extensive profile and

KUFA

Window systems is the leading manufacturer of plastic frames. This fast-growing

company, founded in 2009, provides an extensive profile and

Orion Beton BV is one of the first clients of Matrix Software. "Our relationship is long-standing and close," emphasizes Verheij. "We personally know all the people working for Matrix Software in Winterswijk. This allows us to have short communication lines and enables us to quickly address any questions or issues. For us as a concrete producer, this is absolutely essential, as our production must not come to a halt."

Orion Beton BV is one of the first clients of Matrix Software. "Our relationship is long-standing and close," emphasizes Verheij. "We personally know all the people working for Matrix Software in Winterswijk. This allows us to have short communication lines and enables us to quickly address any questions or issues. For us as a concrete producer, this is absolutely essential, as our production must not come to a halt."

Like Kumij, Transcarbo and Smits Bedrijven Gemert, Europrovyl is part of the VHZ Group. For more than half a century, the company has been a leader in producing, supplying, and assembling plastic facade elements, including complete project management. From frames to doors, windows and sliding doors. “We excel in conceptual new construction, but we are also strong in traditional new construction and renovation projects,” says Van der Velde. “We tackle small and large projects, from one to several hundred homes. With four production locations, approximately 450 skilled employees and a total production of an average of 660 frames per day, we are the market leader in the Netherlands.”

Like Kumij, Transcarbo and Smits Bedrijven Gemert, Europrovyl is part of the VHZ Group. For more than half a century, the company has been a leader in producing, supplying, and assembling plastic facade elements, including complete project management. From frames to doors, windows and sliding doors. “We excel in conceptual new construction, but we are also strong in traditional new construction and renovation projects,” says Van der Velde. “We tackle small and large projects, from one to several hundred homes. With four production locations, approximately 450 skilled employees and a total production of an average of 660 frames per day, we are the market leader in the Netherlands.”

Akker Metaal was founded in 1973. Started in an old forge in Schaijk, the family business has developed considerably. Since 2006 it has been in a new and modern building on the Ketelmeer in Oss, which was expanded significantly four years later. Thanks to a new hall of 1,500 m2, the total production area is approximately 5,000 m2. With various new and innovative machines and 20 skilled in-house employees, Akker Metaal can serve every customer demand.

Akker Metaal was founded in 1973. Started in an old forge in Schaijk, the family business has developed considerably. Since 2006 it has been in a new and modern building on the Ketelmeer in Oss, which was expanded significantly four years later. Thanks to a new hall of 1,500 m2, the total production area is approximately 5,000 m2. With various new and innovative machines and 20 skilled in-house employees, Akker Metaal can serve every customer demand.