To minimize error margins, our production is controlled directly from the software

Patrick Verheij

Head of engineering Orion Beton BV

Customization, quality, and innovation. These are the core values of Orion Beton BV, which produces a variety of precast concrete products in its production halls in Enschede. While one hall manufactures prestressed wide slabs, beam floors, unit floors, and special products, the other hall focuses entirely on the production of traditionally reinforced wide slabs. In this hall, an advanced carousel system is installed, allowing the moulds to follow a logical production sequence through all necessary production steps. Additionally, the hall houses a bending machine for shaping reinforcement bars, enabling Orion Beton to supply additional reinforcement and create and weld reinforcement cages.

Patrick Verheij is the Head of Engineering at Orion Beton BV. Starting as an external draftsman in 1996, he joined the company as a permanent employee in 2002. At that time, Orion Beton BV was already involved in automation. Production steps were being controlled from an AutoCAD drawing, aiming for more precision, speed, and efficiency in production, he explains. "Over the years, this automation has been continuously developed, from rebar machines to spacer machines and plotters that automatically lay out the moulds. In the coming years, we look forward to further advancing this automation, supported by software partners such as Matrix Software."

Unique formwork provisions

With automation, Orion Beton BV is also addressing the growing shortage of skilled workers in the industry. "Where we used to produce wide slab floors measuring 3 meters in width, 6 meters in length, and including one or two openings, nowadays various special formwork and cast in materials need to be incorporated," says Verheij. "Think, for example, of requirements for the installation of climate systems and electrical components, which need to be precisely positioned. To minimize errors in this process, our production is directly controlled from the software. The moulds are plotted one-to-one from the AutoCAD drawings. No human hands are involved, preventing, for example, cleverly mitigating measurement errors."

|

|

|

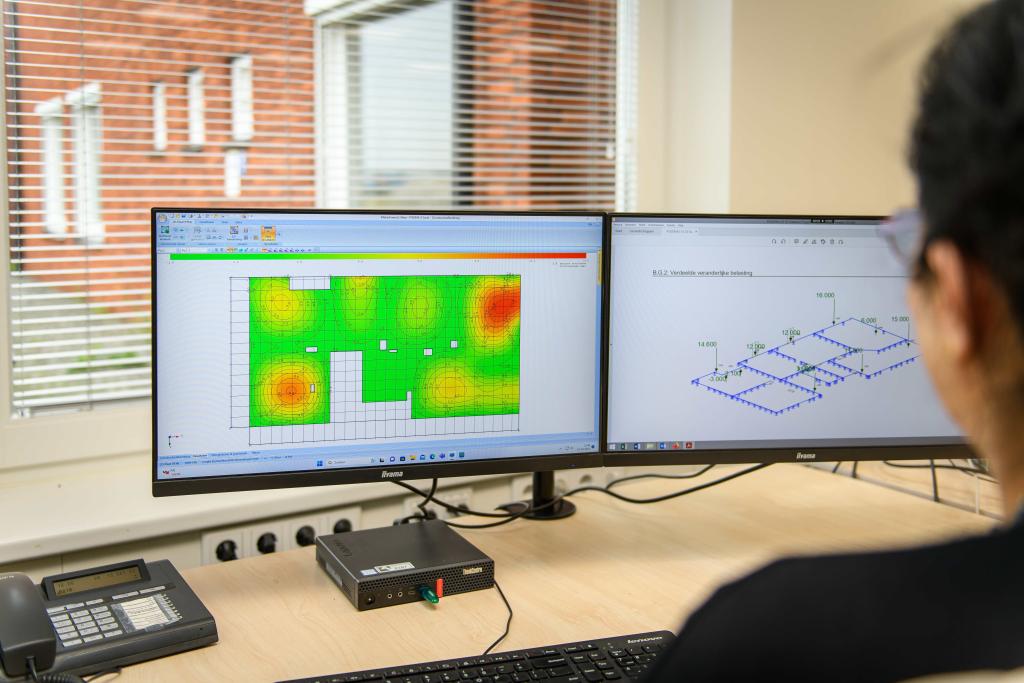

Powerful application

For all overview drawings, laying plans, and detailed drawings, Orion Beton BV uses IC-Prefab CAD; a powerful application from Matrix Software based on AutoCAD, enabling the complete production-ready design of wide slabs, including reinforcement and grids around openings and formwork provisions. "The application also generates machine data, allowing us to control our machines and robots," says Verheij. "To ensure that our planners can still view, check, and edit the data, we also use IC-Elms, which is also used to compile the transports. All data from this application is sent to the ERP system and to the control system in the factory." Finally, Orion Beton BV utilizes various Matrix tools for reinforcement calculations. "From simple two-sided beam programs to four-sided element methods for calculating the floors."

Developments towards 3D

According to Verheij, the choice for Matrix Software was logical because, at that time, there were no comparable software packages available. "And still, Matrix Software's software is unique in its kind. We are truly in a niche market, although we now see several initiatives for 3D software emerging." Drawing concrete floors has been a 2D affair for a long time, he says. "However, the market is increasingly demanding 3D techniques. As a producer, we have to keep up with this trend. Matrix Software is also working on this, but such complex developments and implementations take time. In the coming years, we expect to take new steps in this direction. In the meantime, we can continue to work with IC-Prefab CAD, which also offers the possibility to generate 3D models from the 2D environment."

|

|

|

About Orion Beton BV

Orion Beton BV is one of the first clients of Matrix Software. "Our relationship is long-standing and close," emphasizes Verheij. "We personally know all the people working for Matrix Software in Winterswijk. This allows us to have short communication lines and enables us to quickly address any questions or issues. For us as a concrete producer, this is absolutely essential, as our production must not come to a halt."

Orion Beton BV is one of the first clients of Matrix Software. "Our relationship is long-standing and close," emphasizes Verheij. "We personally know all the people working for Matrix Software in Winterswijk. This allows us to have short communication lines and enables us to quickly address any questions or issues. For us as a concrete producer, this is absolutely essential, as our production must not come to a halt."