We often want to go faster than actually possible, but we still manage with Matrix!

Mark Vleeshouwers

Geelen Beton

Running smoothly

For Mark Vleeshouwers van Geelen Concrete, working with Matrix is a daily routine occupation. As chief engineering of two large concrete factories, he likes to see that everything runs smoothly, because time is money. And with the help of Matrix they can rely on maximum efficiency in the design and production process. "A lot of of our products are unique and that means custom drawings and calculations. Moreover, we want the smallest possible error margin, some extreme precision required. Our customers count on us and we count on Matrix!"

Accurate to the millimeter

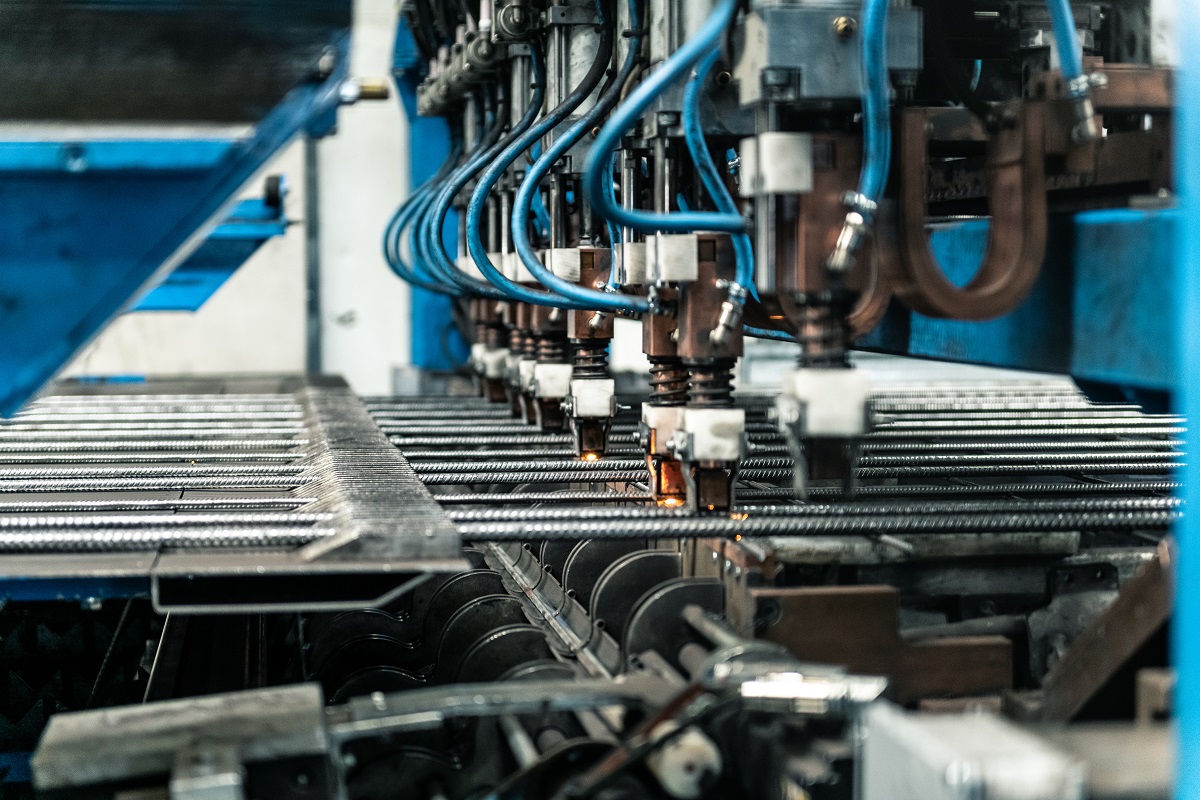

Vleeshouwers is very enthusiastic about the performance of Matrix. “Look, we make everything here: floors, walls, columns, stairs. When it comes to prefab elements, we know almost no boundaries. Especially for our wide plates We use Matrix for ribbed floors. They have IC Prefab from the past iTConcrete improved so that you actually have every design problem can tackle. And that is extremely pleasant because we use our engineering do it completely indoors. To give an example: we make our own nets with specific collapse facilities. In terms of engineering and requires a powerful tool, because you want to make your nets like this that the reinforcement ends up exactly in the right place. For IC Prefab that is no problem. We can work out our floors quickly down to the detailed level, no matter how complex they are. And then the software automatically generates all required production data."

Continuous development

In other construction sectors, standard software is used a lot. In the concrete industry cannot. There it is always custom work. Vleeshouwers: “Sometimes you must immediately identify a specific solution. Sit with Matrix programmers who often do something like that within half a day and that is really an outcome. That software is so fast! I know they are based on the existing AutoCAD application have been further developed. The challenge was to migrate the AutoCAD application to a 3D environment and suitable for BIM: schematize buildings into a 3D model. The result is Matrix IC-Prefab, a powerful add-on to existing drawing programs, with which we can draw in AutoCAD and now also within Revit. Then you get all the efficiency at the very top: the same schedule, the same settings that you can adjust, the same output for machines. Imagine what a time that saves, to name but a few not to mention the ever smaller error margins!"

From drawing to counting

The co-creation between Geelen and Matrix goes further than just the drawing software. There must also be calculated. “Our constructors and engineers artists take care of two sides of the same product. One draws, the other draws counts. Many checks are still needed over and over again, but how beautiful would that be would it be if all that happened automatically? Well, it's time! A Matrix already had a powerful tool, they now have a user-friendly skin built around it and the result is MatrixLigger: new calculation software for system floors, which is also suitable for our competitive colleagues. And that you can link to the drawing software. I think that is unique in the Netherlands and perhaps also for the entire prefab industry in Europe."

Think fast, switch quickly

Software development is always a process that you go together, especially if you want to keep innovating. “Our people communicate directly with Matrix, "says Vleeshouwers. “That works great because Matrix is there itself is completely furnished. In terms of speed, accessibility, know-how, software planning: it's all right. We always get the right people so that we never lose time and no information is lost. Generic improvements are always implemented quickly and specific requirements fitted tightly. Smart switching, that is actually an integral part of our relationship! This also makes it much easier to quickly get adequate link between drawing and calculation software. And who knows what the future holds brings even more. It's just really nice if the experts you work with on one have enough word."

About Geelen Beton

Geelen Concrete has a long history as a family business. Founded in 1923, the

factory initially focused on the manual manufacture of concrete products.

The emphasis was immediately on quality, reliability and innovation.

In two very modern factories in Wanssum and Posterholt become the most

various system floors and concrete elements manufactured. As one of the

Geelen Beton has the people and the resources to be major players in the market

translate all questions from clients into prefab concrete elements with a

great aesthetic value. The engineering takes place completely in-company,

complex construction issues are not avoided. Also

the company contributes to the development of new production techniques, with

an emphasis on sustainability. This is partly due to the use of modern

technical and digital tools, and through close cooperation with external

experts, scientists and suppliers.

Geelen Concrete has a long history as a family business. Founded in 1923, the

factory initially focused on the manual manufacture of concrete products.

The emphasis was immediately on quality, reliability and innovation.

In two very modern factories in Wanssum and Posterholt become the most

various system floors and concrete elements manufactured. As one of the

Geelen Beton has the people and the resources to be major players in the market

translate all questions from clients into prefab concrete elements with a

great aesthetic value. The engineering takes place completely in-company,

complex construction issues are not avoided. Also

the company contributes to the development of new production techniques, with

an emphasis on sustainability. This is partly due to the use of modern

technical and digital tools, and through close cooperation with external

experts, scientists and suppliers.