MatrixWindows All-in-1

Matrix Software has further developed the software solution MatrixWindows into a total concept for carpentry factories. The current developments for 2021 are for working in the cloud and are part of the vision of window frame design in BIM and the vision of a digital, paperless frame factory.

All-in-1

The basis of MatrixWindows is formed by the software for window & doors technology: the calculation, the work preparation and the CNC control of production machines. This basis has been developed considerably in recent years and expanded with more and more functions for the business office: from relationship and project management to planning, deliveries, invoicing and subsequent costing. The latest development focuses on working in the cloud and on the digital and paperless factory. MatrixWindows is an All-in-1 total concept with which all departments can work together seamlessly and efficiently and have the correct information online, in real time.

.png)

In the cloud

MatrixKozijn is a proven and reliable solution that runs on traditional computers and servers. Matrix Software has opted for a strategy in which this solution is expanded step by step with functions that work in the cloud. Time registration and the online webshop are already existing online applications. The all-new MatrixWindows Management Execution System (MES) was recently added to this. And options for relationship management (CRM) and project management (ERP / MRP) on mobile devices such as smartphones and tablets are under development. This strategy ensures that the proven and stable solutions are constantly being expanded with web and app applications to work digitally and paperless.

The digital, paperless factory

The latest development MatrixWindows MES ensures that no thick packages of paper with drawings and production lists go into the factory anymore. All the necessary information does not have to be prepared first, but is immediately available digitally and can be called up at any workplace. Per department can be adjusted which data is available. Frame parts can be recognized with barcodes, QR codes or RFID chips. Scanning can be done with hand scanners or via scanners mounted on machines, work tables or means of transport. MatrixWindows CNC has special algorithms that calculate a suitable place in the frame wood to make a borehole for the RFID chip, so that the chip and machine operations do not touch each other. This is important not only during production, but also later during construction and for maintenance purposes. Finally, MatrixWindows MES arranges the entire expedition, including the deployment and location management of the transport trestles.

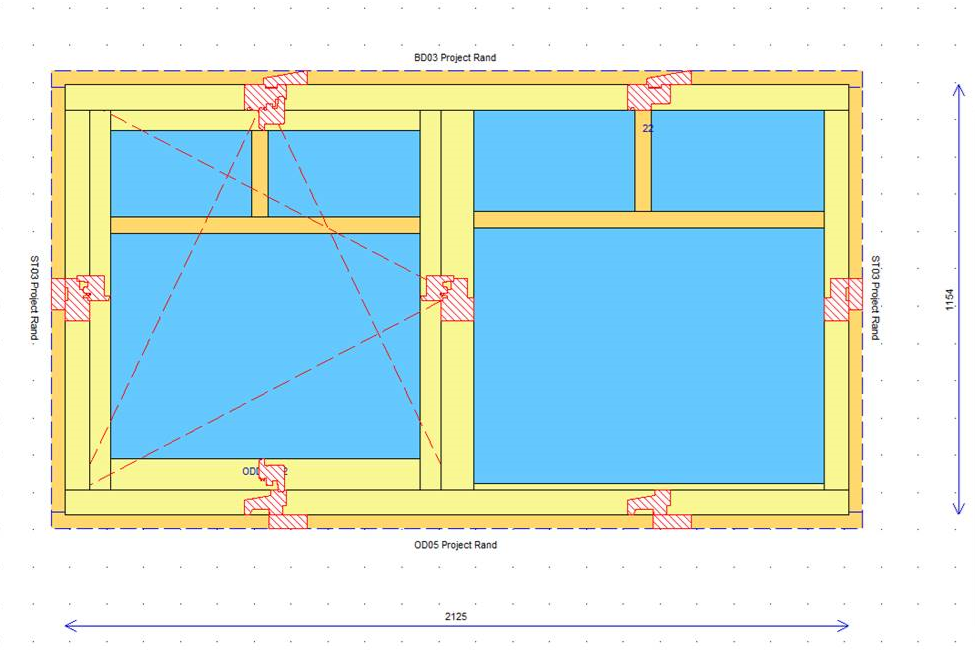

Windows & doors technology

In addition to all these new cloud developments, the basis of MatrixWindows is also being further developed. A completely new function for applying cavity laths is under development. In addition, there will be an improved representation of all cross-sections of frame timber, edging timber, window timber and door timber, both in the frame views and in the production states. And within MatrixWindows CNC the control of glue robots, paint robots and curced window frames is available.

BIM: 3D and IFC

There are also new developments in the field of BIM. First of all, MatrixWindows has been expanded with a new 3D display of window frames. The lightning-fast and proven 2D input and display of frames will remain. This has been expanded with a 3D view. With the help of a clipping function, the details are shown in the frame. A second new BIM development is the use of the IFC format. The first step in this is to export window frames in the IFC format. This gives project partners access to IFC frame models “as built”. The next step in this development is to import frame models based on IFC.

For more information: