Text: Roel van Gils

Images: Matrix Software

Source: Beton & Staalbouw

Prefab concrete factories benefit from a scalable IT landscape. But before they can take that step, they first must think about product standardization, says Heico Heuver, director of Matrix Software. “Everyone talks about the smart industry or industry 4.0, but few parties take the bull by the horns.”

Matrix Software has a complete proposition for concrete prefab floor and wall systems: from ERP and factory logistics to CAD/CAM and structural analyses. “Many companies that are busy replacing outdated software often look back at the past,” Heuver notes. “The result is that substantial investments are being made in solutions to support existing business processes. Unfortunately, this regularly turns into a disappointment because it leads to anything but a modern, scalable, and flexible solution. Instead, you are just building customization again. A copy of the outdated system, but with a modern twist.”

Heico Heuver, director of Matrix Software.

Product standardization

Automation starts with product standardization. “And that primarily means re-educating the product range and sales,” advises Heuver. “The sales department will have to entice buyers to purchase standard products instead of specials as much as possible. A production environment based on exceptions is one of the main reasons many parties get stuck when redesigning the IT landscape. As soon as there is product standardization, we can create a flexible and scalable IT landscape comprising commodities. In other words, standard parts are easy to replace. It makes a company much more decisive and future-proof than opting for one large, customized environment, as was common practice in the concrete industry in the past.”

With the IMPACT GO app, information can be retrieved from the workplace via a mobile device.

Scalable IT landscape

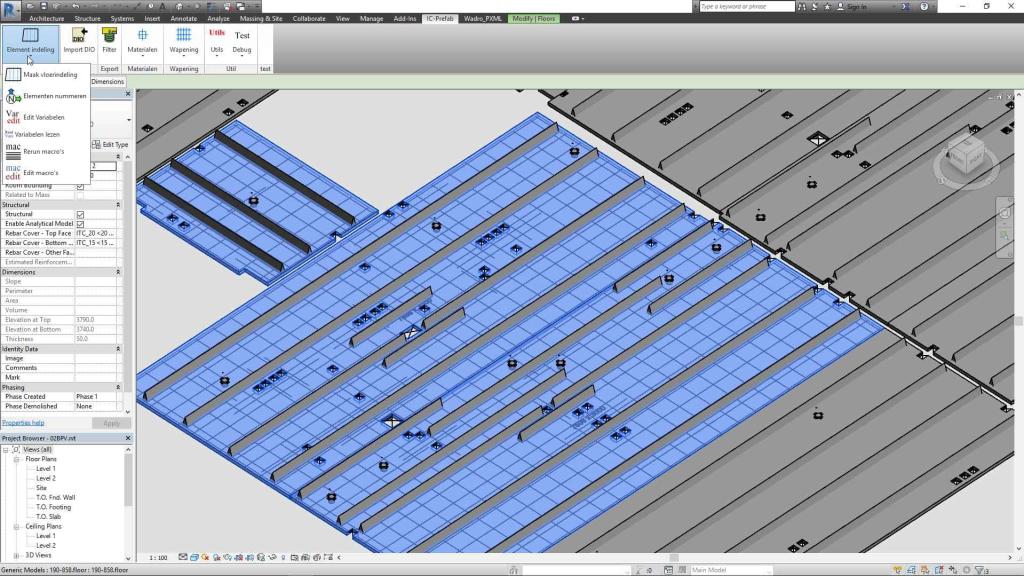

Matrix Software can fulfil all commodities within a scalable IT landscape, where we have finance partnerships with leading financial software suppliers. Heuver explains: “MatrixProject is our ERP solution, Impact Production focuses on the planning of the factory, the stock yard and logistics, MatrixLigger is intended for the structural calculation of all prefab floor types, and IC-Prefab is the CAD/CAM environment for the realization of a digital twin. Finally, with the Impact GO app, we retrieve all information from the work floor via mobile devices and send the necessary information back. All those commodities speak the same language and exchange information with each other for maximum grip and control. The commodities are also interchangeable, resulting in an extremely flexible IT landscape.”

In 2023, Matrix Software will persuade the market to focus on scalable IT architecture. “One of our two founders recently retired and transferred his shares to StruSoft Group, a Norwegian/Swedish investment company with several construction software companies in its portfolio. This enables us to introduce Impact Production and Impact GO to the Dutch market. Linked to MatrixProject, MatrixLigger, and IC-Prefab, it completes our proposition for prefab concrete factories.”

Drawing/modelling wide slab floors in IC-Prefab.